QTY15-15

ZCJK

8474802000

| Quantity: | |

|---|---|

| Features: 1.Frequency conversion technology is adopted on this machine to save about 30% electricity power. 2.This machine, is a fully automatic production line, the production efficiency is highly improved. It can make various type of blocks, bricks and pavers. 3.Vibration superiority: table and vibration vibrating work together to achieve products of high density. The vibrating force is over 180kn 4. There are rubber vibration absorbing shims on both the upper mould and vibration platform, which can reduce energy consumption. 5. This QTY15-15 fully automatic block production line is equipped with airbag cylinder for absorbing vibration 6. This block production line is designed with integrated platform for both vibrating and molding, the machine is with high vibrating efficiency. The vibrating frequency is over 4850 time per minute. 7. The transmission shaft is adopted for tow motors to drive vibrating box. This design can facilitate power conservation and prevent the inconsistency from vibrating motors 8.The double lined aero vibration resisting system is applied to alleviate the vibrating impact on other parts of the block machine. For more detail,please talk to the service teams on line. |

| Production rate | |||

| Block type | measurements | pcs/mould | pcs/8 hours |

| Standard brick | 240x115x51mm | 84 | 161280 |

| Stand hollow blocks | 400x200x200mm | 15 | 28800 |

| Paver | 200x100x60mm | 55 | 105600 |

| Specification | |||

| Vibrating Force | 180KN | ||

| Pallet size | 1400*1200*30MM | ||

| Power of block forming machine | 64KW | ||

| Weight of block forming machine | 17.2T | ||

| Container required for shipping | 40HQ*4 | ||

| Items included for the production line | |||

| Name | Quantity | Name | Quantity |

| QTY15-15 block forming machine | 1 | Belt conveyer (8 meters) | 1 |

| Automatic block conveyor | 1 | JS1000 concrete mixer | 1 |

| Automatic pallet feeder | 1 | Three stage batching system | 1 |

| Hydraulic unit | 1 | Stacker | 1 |

| Control systtem(PLC control system from German Siemens) | 1 | Free mould | 1 |

| Automatic pallet pusher | 1 | Color feeder | 1 |

| JW500 mixer(for mixing color) | 1 | Belt conveyor (6 meters) for delivering color | 1 |

| For more detail, please talk to the serice agents online | |||

| Production site from customers | ||

|  |  |

|  |  |

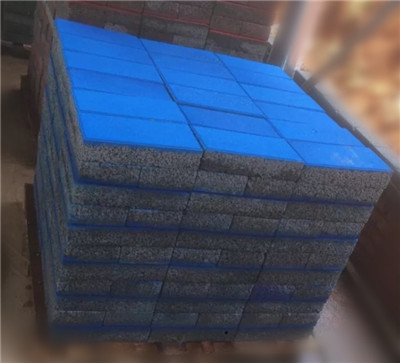

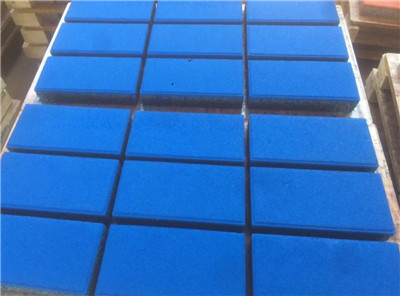

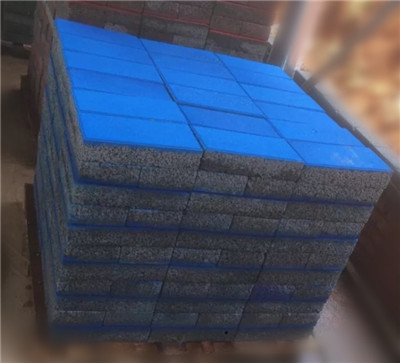

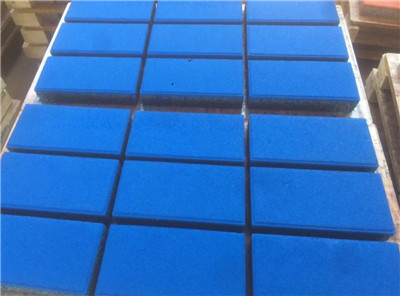

| the block/brick/paver made by this fully automatic block machine,where they will be used |

|

| About ZCJK block machine ZCJK is a brand, and a trademark. 1.ZCJK with Two factories in China, one is in Beijing, another is in Wuhan, it makes leadinf time shorter, for clients to receive the block machine sooner 2.ZCJK, has been already in the this business for more than 18 years. The block machines from ZCJK exported to over 103 countries, especially in Asia, Africa and South America. 3.ZCJK, with after-sales services team in Mozambique, India and South America, the clients can get the after-sales service in the soonest time. 4.ZCJK, has cooperated with many Foreigh Embassies in China, such as: the embassy of Tanzania, Uganda, Nigeria, Namibia, Ghana and Malawi. |

| How to contact us Any help needed,you can please contact us by: Whatsapp:+86 13439309361 Email:henry@zcjk.com, linda@zcjk.com |

| Features: 1.Frequency conversion technology is adopted on this machine to save about 30% electricity power. 2.This machine, is a fully automatic production line, the production efficiency is highly improved. It can make various type of blocks, bricks and pavers. 3.Vibration superiority: table and vibration vibrating work together to achieve products of high density. The vibrating force is over 180kn 4. There are rubber vibration absorbing shims on both the upper mould and vibration platform, which can reduce energy consumption. 5. This QTY15-15 fully automatic block production line is equipped with airbag cylinder for absorbing vibration 6. This block production line is designed with integrated platform for both vibrating and molding, the machine is with high vibrating efficiency. The vibrating frequency is over 4850 time per minute. 7. The transmission shaft is adopted for tow motors to drive vibrating box. This design can facilitate power conservation and prevent the inconsistency from vibrating motors 8.The double lined aero vibration resisting system is applied to alleviate the vibrating impact on other parts of the block machine. For more detail,please talk to the service teams on line. |

| Production rate | |||

| Block type | measurements | pcs/mould | pcs/8 hours |

| Standard brick | 240x115x51mm | 84 | 161280 |

| Stand hollow blocks | 400x200x200mm | 15 | 28800 |

| Paver | 200x100x60mm | 55 | 105600 |

| Specification | |||

| Vibrating Force | 180KN | ||

| Pallet size | 1400*1200*30MM | ||

| Power of block forming machine | 64KW | ||

| Weight of block forming machine | 17.2T | ||

| Container required for shipping | 40HQ*4 | ||

| Items included for the production line | |||

| Name | Quantity | Name | Quantity |

| QTY15-15 block forming machine | 1 | Belt conveyer (8 meters) | 1 |

| Automatic block conveyor | 1 | JS1000 concrete mixer | 1 |

| Automatic pallet feeder | 1 | Three stage batching system | 1 |

| Hydraulic unit | 1 | Stacker | 1 |

| Control systtem(PLC control system from German Siemens) | 1 | Free mould | 1 |

| Automatic pallet pusher | 1 | Color feeder | 1 |

| JW500 mixer(for mixing color) | 1 | Belt conveyor (6 meters) for delivering color | 1 |

| For more detail, please talk to the serice agents online | |||

| Production site from customers | ||

|  |  |

|  |  |

| the block/brick/paver made by this fully automatic block machine,where they will be used |

|

| About ZCJK block machine ZCJK is a brand, and a trademark. 1.ZCJK with Two factories in China, one is in Beijing, another is in Wuhan, it makes leadinf time shorter, for clients to receive the block machine sooner 2.ZCJK, has been already in the this business for more than 18 years. The block machines from ZCJK exported to over 103 countries, especially in Asia, Africa and South America. 3.ZCJK, with after-sales services team in Mozambique, India and South America, the clients can get the after-sales service in the soonest time. 4.ZCJK, has cooperated with many Foreigh Embassies in China, such as: the embassy of Tanzania, Uganda, Nigeria, Namibia, Ghana and Malawi. |

| How to contact us Any help needed,you can please contact us by: Whatsapp:+86 13439309361 Email:henry@zcjk.com, linda@zcjk.com |