Introduction:

Function: standard bricks, blocks, perforated bricks, paving bricks etc. can be produced with various molds. This is also an interlocking brick making machine, it can make interlocking brick automatically. Process: It is manpower saving for its operating rod control, automatic pallet conveyance, automatic leading-out and hydraulic molding. |

Technical specifications

Production capacity | Hollow brick | 400*200*200mm | 4pcs/mould |

Standard brick | 240*115*53mm | 26pcs/mould | |

Paving brick | 200*100*60mm | 14pcs/mould | |

Cycle time | 15-25s | ||

Shift output | Hollow brick | 400*200*200mm | 6400pcs/8h |

Standard brick | 240*115*53mm | 41600pcs/8h | |

Paving brick | 200*100*60mm | 20160pcs/8h | |

Power | 38KW | ||

Weight | 4.5T | ||

Container required | 1*20GP | ||

Vibrating force | 60KN | ||

Bamboo pallet size | 880*550*20mm | ||

Structure:

| (1)It is solid and durable for its four guiding columns and patent lengthening sleeve guide. (2)The forced mold synchronous structure gives the products perfect shape and high strength. And the stable demolding process ensures the output of more finished products. (3)The QTY4-18 brick making machine frame is welded by special thick steel rectangle welding techniques, thus it is strong, durable and can resist vibration. We use the steel produced by famous steel manufactures Shougang Group. The service life of main machine is more than 10 years. (4) There is electric motor and belt in brick conveyor machine, it can convey the pallets when the bricks come out, it prevent collisions between pallets and avoid the break od bricks. It is more automatically and more durable. (5)The connecting rod of material feeder use the whole steel casting, which is stronger and more durable |

(6)The material feeding system uses broken arch structure, when feeding materials, kick fork swings back and forth quickly to feed materials evenly, and fill the mold with materials in every corner. It can ensure the high rate of (7)Vibration motor use heat-resistant motor which can continue working safely under 130℃ for long time, the extreme temperature is up to 180℃, it’s especially suitable for high temperature region. (8)Circulating water colling system. The cooler is customized specially, the water pipe inside are all copper pipe, it have very good cooling effect. So the machine can ensure the temperature of hydraulic oil not very high and the machine can work for a long time. So the machine can produce normally in hot weather in Africa. |

| Production site from customers | ||

|  |  |

|  |  |

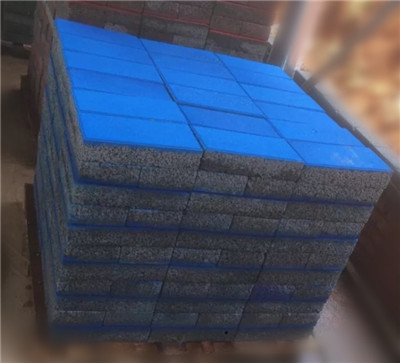

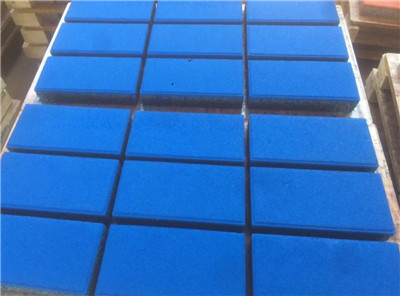

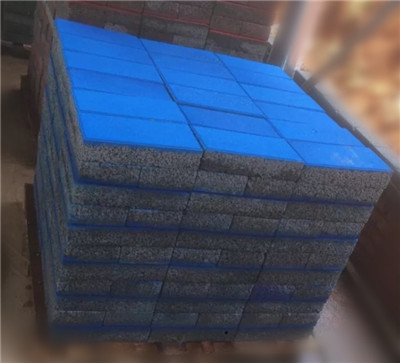

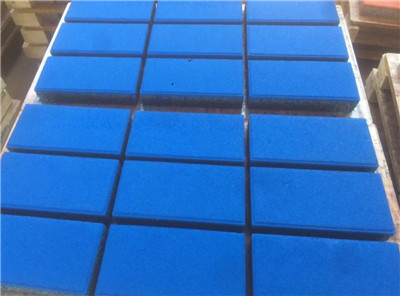

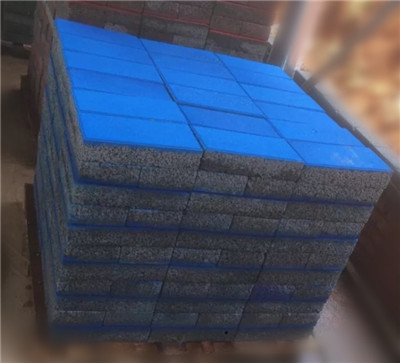

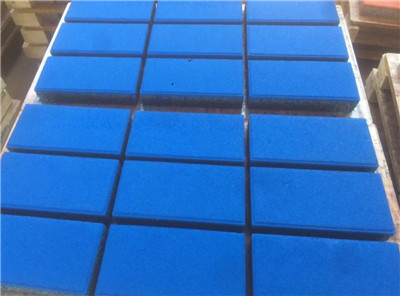

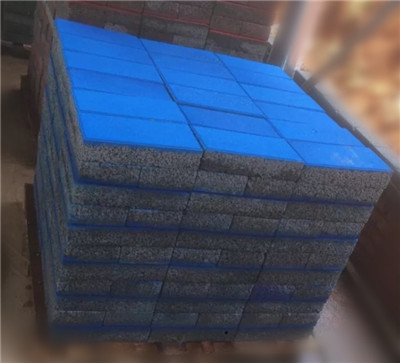

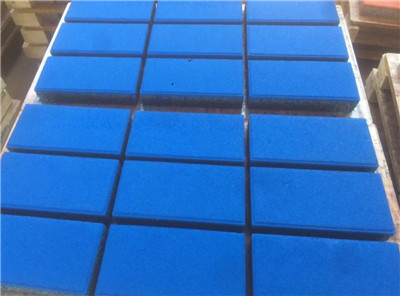

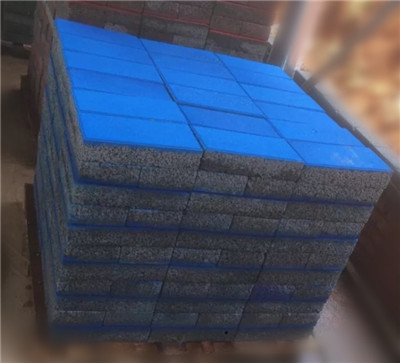

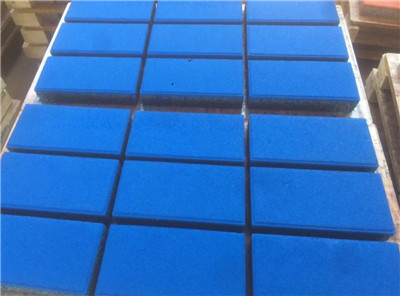

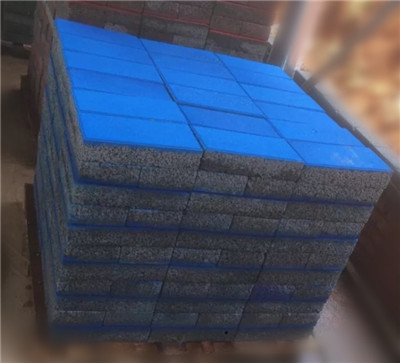

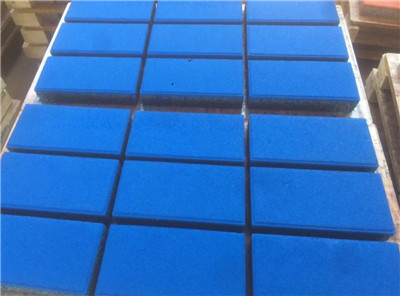

| the block/brick/paver made by this fully automatic block machine,where they will be used |

|

| About ZCJK block machine ZCJK is a brand, and a trademark. 1.ZCJK with Two factories in China, one is in Beijing, another is in Wuhan, it makes leadinf time shorter, for clients to receive the block machine sooner 2.ZCJK, has been already in the this business for more than 18 years. The block machines from ZCJK exported to over 103 countries, especially in Asia, Africa and South America. 3.ZCJK, with after-sales services team in Mozambique, India and South America, the clients can get the after-sales service in the soonest time. 4.ZCJK, has cooperated with many Foreigh Embassies in China, such as: the embassy of Tanzania, Uganda, Nigeria, Namibia, Ghana and Malawi. |

| How to contact us Any help needed,you can please contact us by: Whatsapp:+86 13439309361 Email:henry@zcjk.com, linda@zcjk.com |

Introduction:

Function: standard bricks, blocks, perforated bricks, paving bricks etc. can be produced with various molds. This is also an interlocking brick making machine, it can make interlocking brick automatically. Process: It is manpower saving for its operating rod control, automatic pallet conveyance, automatic leading-out and hydraulic molding. |

Technical specifications

Production capacity | Hollow brick | 400*200*200mm | 4pcs/mould |

Standard brick | 240*115*53mm | 26pcs/mould | |

Paving brick | 200*100*60mm | 14pcs/mould | |

Cycle time | 15-25s | ||

Shift output | Hollow brick | 400*200*200mm | 6400pcs/8h |

Standard brick | 240*115*53mm | 41600pcs/8h | |

Paving brick | 200*100*60mm | 20160pcs/8h | |

Power | 38KW | ||

Weight | 4.5T | ||

Container required | 1*20GP | ||

Vibrating force | 60KN | ||

Bamboo pallet size | 880*550*20mm | ||

Structure:

| (1)It is solid and durable for its four guiding columns and patent lengthening sleeve guide. (2)The forced mold synchronous structure gives the products perfect shape and high strength. And the stable demolding process ensures the output of more finished products. (3)The QTY4-18 brick making machine frame is welded by special thick steel rectangle welding techniques, thus it is strong, durable and can resist vibration. We use the steel produced by famous steel manufactures Shougang Group. The service life of main machine is more than 10 years. (4) There is electric motor and belt in brick conveyor machine, it can convey the pallets when the bricks come out, it prevent collisions between pallets and avoid the break od bricks. It is more automatically and more durable. (5)The connecting rod of material feeder use the whole steel casting, which is stronger and more durable |

(6)The material feeding system uses broken arch structure, when feeding materials, kick fork swings back and forth quickly to feed materials evenly, and fill the mold with materials in every corner. It can ensure the high rate of (7)Vibration motor use heat-resistant motor which can continue working safely under 130℃ for long time, the extreme temperature is up to 180℃, it’s especially suitable for high temperature region. (8)Circulating water colling system. The cooler is customized specially, the water pipe inside are all copper pipe, it have very good cooling effect. So the machine can ensure the temperature of hydraulic oil not very high and the machine can work for a long time. So the machine can produce normally in hot weather in Africa. |

| Production site from customers | ||

|  |  |

|  |  |

| the block/brick/paver made by this fully automatic block machine,where they will be used |

|

| About ZCJK block machine ZCJK is a brand, and a trademark. 1.ZCJK with Two factories in China, one is in Beijing, another is in Wuhan, it makes leadinf time shorter, for clients to receive the block machine sooner 2.ZCJK, has been already in the this business for more than 18 years. The block machines from ZCJK exported to over 103 countries, especially in Asia, Africa and South America. 3.ZCJK, with after-sales services team in Mozambique, India and South America, the clients can get the after-sales service in the soonest time. 4.ZCJK, has cooperated with many Foreigh Embassies in China, such as: the embassy of Tanzania, Uganda, Nigeria, Namibia, Ghana and Malawi. |

| How to contact us Any help needed,you can please contact us by: Whatsapp:+86 13439309361 Email:henry@zcjk.com, linda@zcjk.com |

Technical Specification

| Production capacity | Standard block | 240*115*53mm | 26pcs/mould |

| Hollow block | 400*200*200mm | 4pcs/mould | |

| Paving block | 200*100*60mm | 16pcs/mould | |

| Cycle time | 18-25s | ||

| Per hour output | Standard block | 240*115*53mm | 5200pcs/hour |

| Hollow block | 400*200*200mm | 800pcs/hour | |

| Paving block | 200*100*60mm | 2880pcs/hour | |

| Shift output | Standard block | 240*115*53mm | 41600pcs/8hours |

| Hollow block | 400*200*200mm | 6400pcs/8hours | |

| Paving block | 200*100*60mm | 23040pcs/8hours | |

| Vibrating force | 68KN | ||

| Power | 24.95KW | ||

| Weight | 4.5T | ||

| Container required | 1*40HQ | ||

| Bamboo pallet size | 1020*550*20mm | ||

Items of Investment:

| Items | Quantity |

| QTY4-20A block making machine | 1 |

| Block conveyor machine | 1 |

| Pallet feeder | 1 |

| Conveyer belt | 1 |

| JDC350 mixer | 1 |

| Control system | 1 |

| Manual cart | 2 |

| Free mould | 1 |

| Production site from customers | ||

|  |  |

|  |  |

| the block/brick/paver made by this fully automatic block machine,where they will be used |

|

| About ZCJK block machine ZCJK is a brand, and a trademark. 1.ZCJK with Two factories in China, one is in Beijing, another is in Wuhan, it makes leadinf time shorter, for clients to receive the block machine sooner 2.ZCJK, has been already in the this business for more than 18 years. The block machines from ZCJK exported to over 103 countries, especially in Asia, Africa and South America. 3.ZCJK, with after-sales services team in Mozambique, India and South America, the clients can get the after-sales service in the soonest time. 4.ZCJK, has cooperated with many Foreigh Embassies in China, such as: the embassy of Tanzania, Uganda, Nigeria, Namibia, Ghana and Malawi. |

| How to contact us Any help needed,you can please contact us by: Whatsapp:+86 13439309361 Email:henry@zcjk.com, linda@zcjk.com |

| Production site from customers | ||

|  |  |

|  |  |

| the block/brick/paver made by this fully automatic block machine,where they will be used |

|

| About ZCJK block machine ZCJK is a brand, and a trademark. 1.ZCJK with Two factories in China, one is in Beijing, another is in Wuhan, it makes leadinf time shorter, for clients to receive the block machine sooner 2.ZCJK, has been already in the this business for more than 18 years. The block machines from ZCJK exported to over 103 countries, especially in Asia, Africa and South America. 3.ZCJK, with after-sales services team in Mozambique, India and South America, the clients can get the after-sales service in the soonest time. 4.ZCJK, has cooperated with many Foreigh Embassies in China, such as: the embassy of Tanzania, Uganda, Nigeria, Namibia, Ghana and Malawi. |

| How to contact us Any help needed,you can please contact us by: Whatsapp:+86 13439309361 Email:henry@zcjk.com, linda@zcjk.com |

Technical Specification

| Production capacity | Standard block | 240*115*53mm | 26pcs/mould |

| Hollow block | 400*200*200mm | 4pcs/mould | |

| Paving block | 200*100*60mm | 16pcs/mould | |

| Cycle time | 18-25s | ||

| Per hour output | Standard block | 240*115*53mm | 5200pcs/hour |

| Hollow block | 400*200*200mm | 800pcs/hour | |

| Paving block | 200*100*60mm | 2880pcs/hour | |

| Shift output | Standard block | 240*115*53mm | 41600pcs/8hours |

| Hollow block | 400*200*200mm | 6400pcs/8hours | |

| Paving block | 200*100*60mm | 23040pcs/8hours | |

| Vibrating force | 68KN | ||

| Power | 24.95KW | ||

| Weight | 4.5T | ||

| Container required | 1*40HQ | ||

| Bamboo pallet size | 1020*550*20mm | ||

Items of Investment:

| Items | Quantity |

| QTY4-20A block making machine | 1 |

| Block conveyor machine | 1 |

| Pallet feeder | 1 |

| Conveyer belt | 1 |

| JDC350 mixer | 1 |

| Control system | 1 |

| Manual cart | 2 |

| Free mould | 1 |

| Production site from customers | ||

|  |  |

|  |  |

| the block/brick/paver made by this fully automatic block machine,where they will be used |

|

| About ZCJK block machine ZCJK is a brand, and a trademark. 1.ZCJK with Two factories in China, one is in Beijing, another is in Wuhan, it makes leadinf time shorter, for clients to receive the block machine sooner 2.ZCJK, has been already in the this business for more than 18 years. The block machines from ZCJK exported to over 103 countries, especially in Asia, Africa and South America. 3.ZCJK, with after-sales services team in Mozambique, India and South America, the clients can get the after-sales service in the soonest time. 4.ZCJK, has cooperated with many Foreigh Embassies in China, such as: the embassy of Tanzania, Uganda, Nigeria, Namibia, Ghana and Malawi. |

| How to contact us Any help needed,you can please contact us by: Whatsapp:+86 13439309361 Email:henry@zcjk.com, linda@zcjk.com |

| Production site from customers | ||

|  |  |

|  |  |

| the block/brick/paver made by this fully automatic block machine,where they will be used |

|

| About ZCJK block machine ZCJK is a brand, and a trademark. 1.ZCJK with Two factories in China, one is in Beijing, another is in Wuhan, it makes leadinf time shorter, for clients to receive the block machine sooner 2.ZCJK, has been already in the this business for more than 18 years. The block machines from ZCJK exported to over 103 countries, especially in Asia, Africa and South America. 3.ZCJK, with after-sales services team in Mozambique, India and South America, the clients can get the after-sales service in the soonest time. 4.ZCJK, has cooperated with many Foreigh Embassies in China, such as: the embassy of Tanzania, Uganda, Nigeria, Namibia, Ghana and Malawi. |

| How to contact us Any help needed,you can please contact us by: Whatsapp:+86 13439309361 Email:henry@zcjk.com, linda@zcjk.com |